While the length of the bars represents the frequency or cost time or money the bars are arranged with. Diagrams are a great way to identify which problems should be prioritized based on the cumulative effect it has on a system.

Kanban Pull System Kanban System Pulls

The following visual risk management methods can be used to identify risks beforehand.

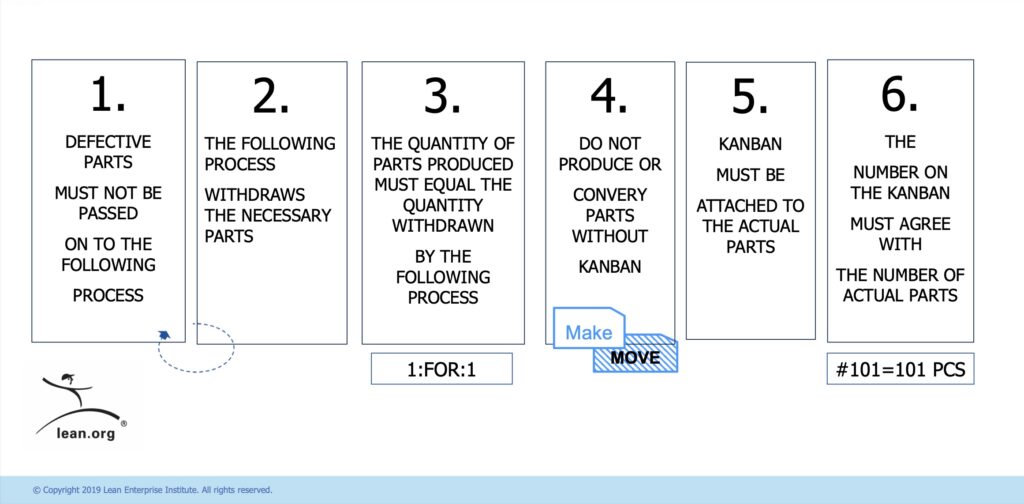

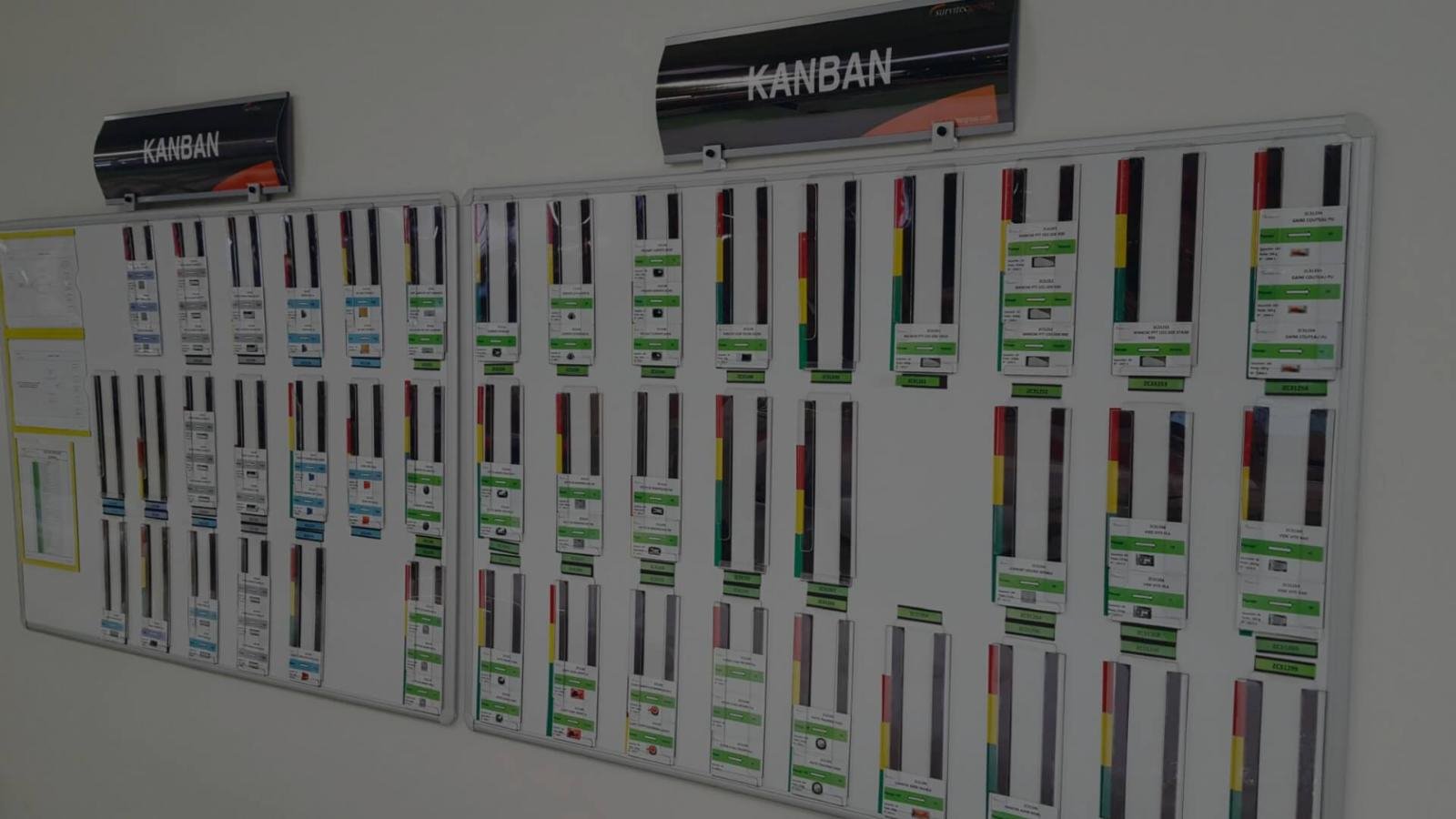

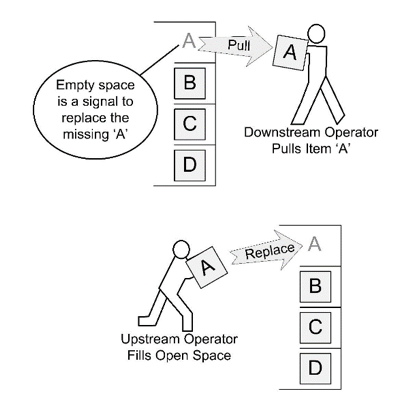

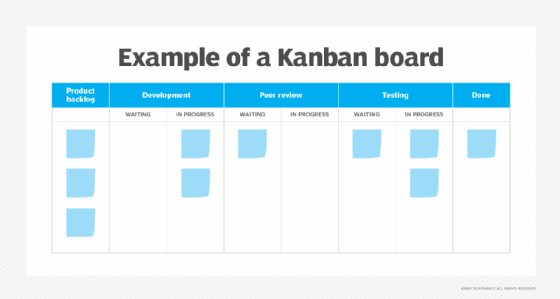

. As a scheduling system for lean and just-in-time production. Kanban project management controls the logistical chain from a production point of view. With the dawn of visual planning boards in software in our era like Trello there are now new uses for Kanban tools and Kanban methods.

Effectively maintain and manage multilevel bill of materials production planning job cards inventory. Developed order entry and inventory management systems for AS400 in RPG400. Full-fledged accounting module covering every aspect of bookkeeping.

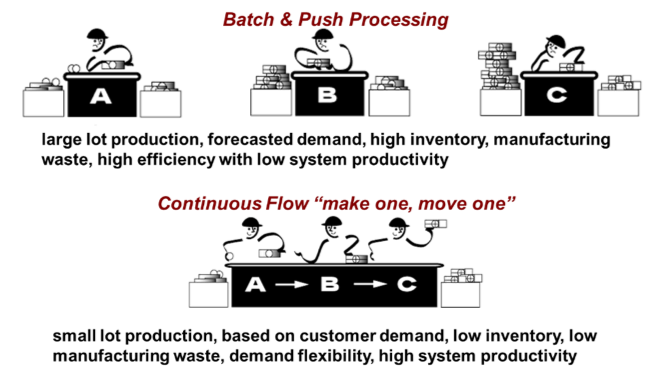

Decision Tree Diagram. Heijunka pronounced hey-june-kuh is a Japanese word that means levelingIn Lean it refers to the leveling of production aimed at improving the flow of a process to better match customer demand reduce waste and decrease or quit batch processing. It forms the foundation of Lean or the Toyota Production System along with the concept of standardized work and Kaizen.

The car company applied it to their lean manufacturing model known as the Toyota production system. Lean manufacturing also uses Kanban a basic scalable and visual scheduling system. An MES is a system that controls and manages production on the factory floor with the goal of reducing the total time needed to produce an order.

It should also show whether the entire system will engage at once or if it is a zoned system that only activates certain areas based on the location of the fire. Manage full employee life cycle right from onboarding payroll attendance expense claims assets to separation. MES Manufacturing execution system A system that controls and manages production on the factory floor with the goal of reducing the total time needed to produce an order.

It also includes arrangement for the prompt remedy or adjustment in case of any deviation so that the production may run according to the original or revised schedule. Kanban in the context of software development can mean a visual process management system that tells what to produce when to produce it and how much to produce inspired by the Toyota Production System and Lean manufacturing. Project production management PPM is a strategic approach that applies theories and principles of operations science to better understand and optimize project delivery.

Developed applications using Microsoft Visual Studio Microsoft Access Borland Delphi and Borland C. While Kanban is a task management system Scrum is a project delivery framework that benefits from Kanban in its task management function. The fire prevention plan should identify what type of suppression element is used and how it will be engaged.

Its focus on best practice principles and adaptable process-based approach makes it applicable to projects of all scopes and sizes within any sector. To Do In Progress and Done. Kanban is also an agile process and its a automated system.

Get a real-time view of your cash flow. An example is the use of a substitute part. Scrum uses the timeboxing principle to deliver value in a 2-4 week.

28 The pull system can be implemented as a kanban. Often called Shop Floor. PRODUCTION CONTROL Production control is the process that keeps a watchful eye on the production flow size of resources along with any deviation from the planned action.

Manufacturing Deviation A temporary change in production or a manufacturing procedure. The planning and controlling of a performance of an activity. This is a visual way of demonstrating the relationship between events and tasks and how they impact one another.

Agile teams use Kanban boards for story-boarding user stories and for backlog planning in software development. This process highlights any bottlenecks or backlogs by their lack of movement from one column to the next so you can address them. What makes PPM unique is the fact it uses actual data from project activities to predict limits and determine what can be genuinely achieved.

A document such as a redlined drawing that has annotations indicating recommended changes to a. We would like to show you a description here but the site wont allow us. Kanbans continuous task management orientation makes it a perfect candidate for both managing project delivery and operational support.

Deviations may be planned or unplanned. Workers can visualize all tasks in a project under one of the headings. PRINCE2 PRojects In Controlled Environments is one of the most popular project management methodologies in the world.

What Is Kanban Methodology Inflectra

What Is Kanban An Overview Of The Kanban Method

Kanban What Is It Lean Enterprise Institute

What Is Kanban Graphic Products

Kanban 4 Steps Inventory Control System Sesa Systems

What Is Kanban Methodology Inflectra

Kanban Pull Systems Ut Center For Industrial Services

Ten Steps To Effective Kanban De

I Just Downloaded A Simple Free Personal Kanban Board For Excel From Tipsographic Com Business Leadership Business Skills Change Management

What Is Kanban A Definition From Whatis Com

Kanban Method Explained Guide 2022

What Is Kanban An Overview Of The Kanban Method

What Is Kanban Graphic Products

Kanban Infographic Kanban Explained Graphic Products

The Official Guide To The Kanban Method Kanban University

Scrum Vs Kanban Ppt Kanban Scrum Software Development

What Is Kanban An Overview Of The Kanban Method

Kanban Pull Systems Ut Center For Industrial Services

Kanban With Examples Creative Safety Supply